About Us

Corporate Philosophy and Vision: Green Manufacturing, Sustainable Collaboration for Shared Success, Quality First

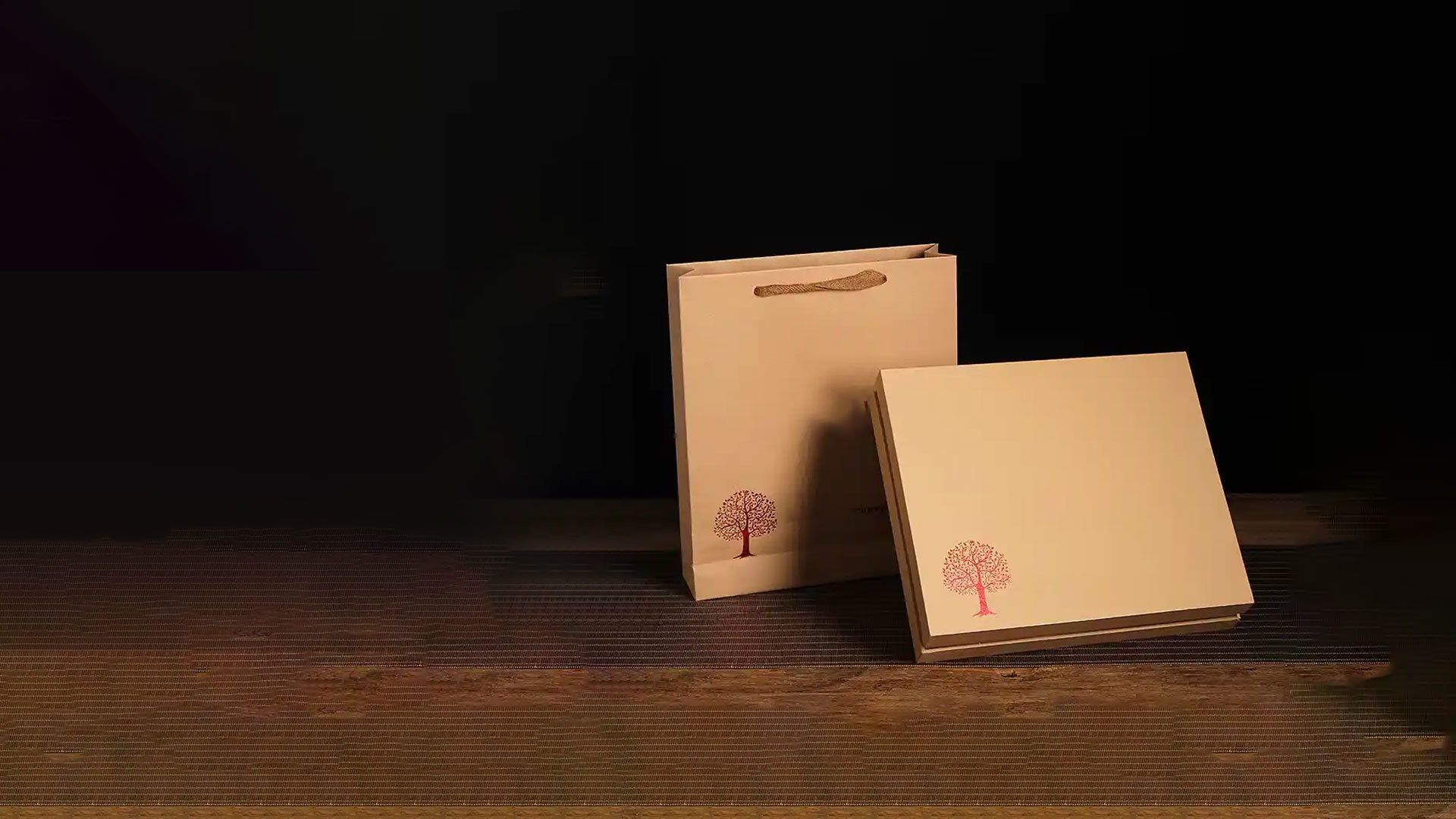

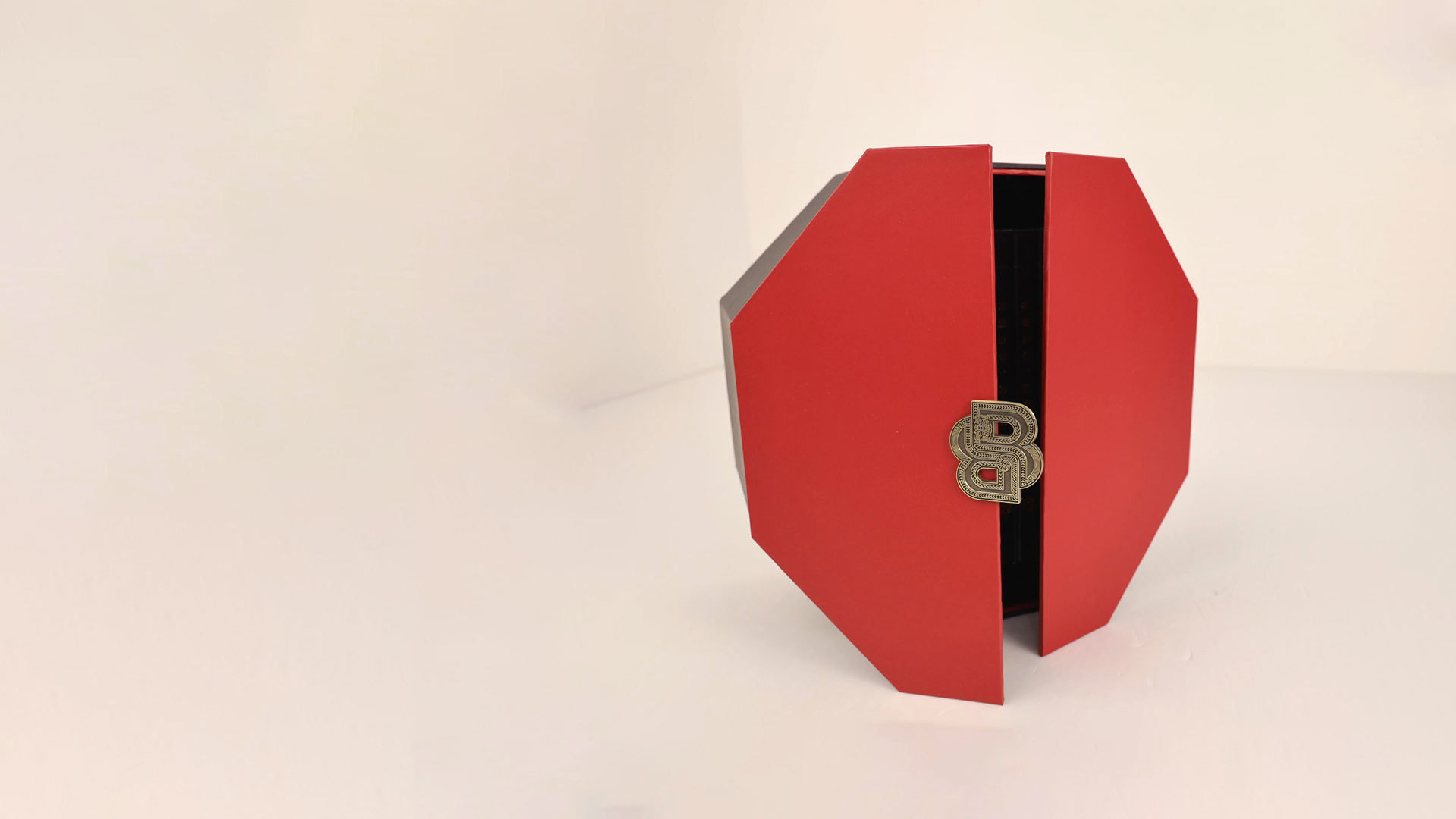

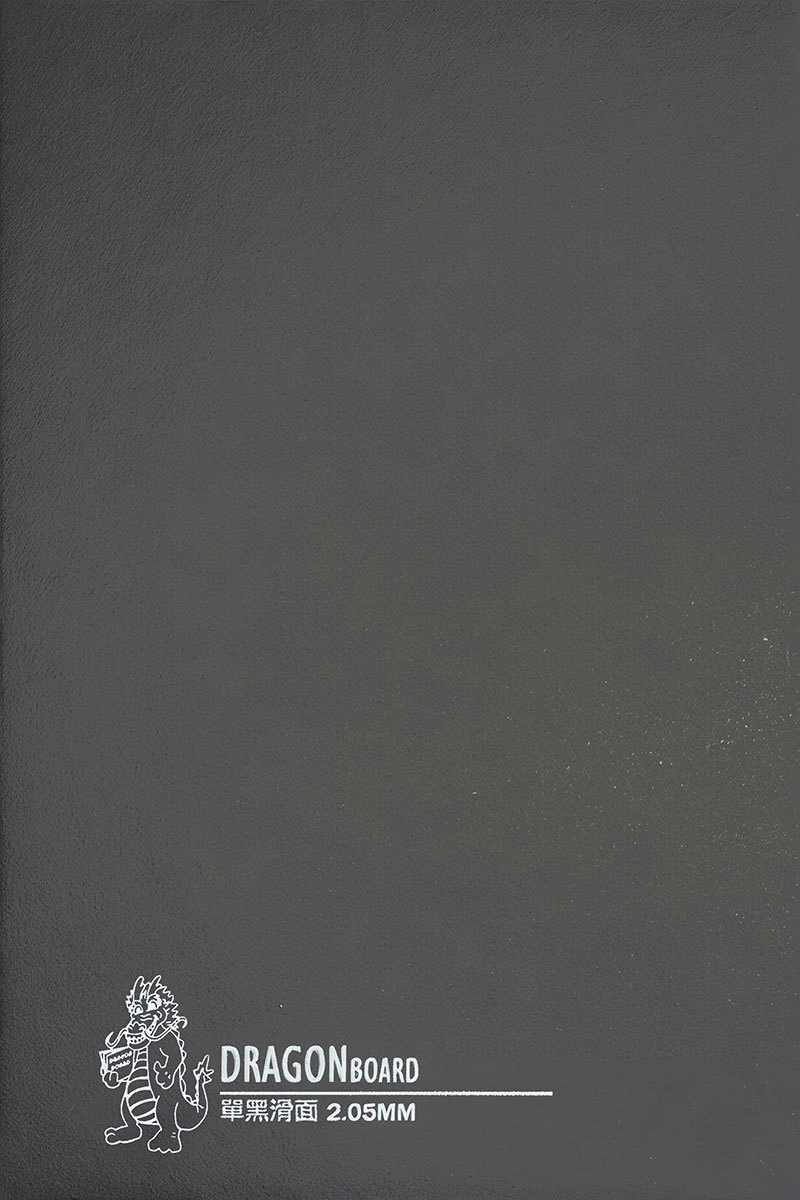

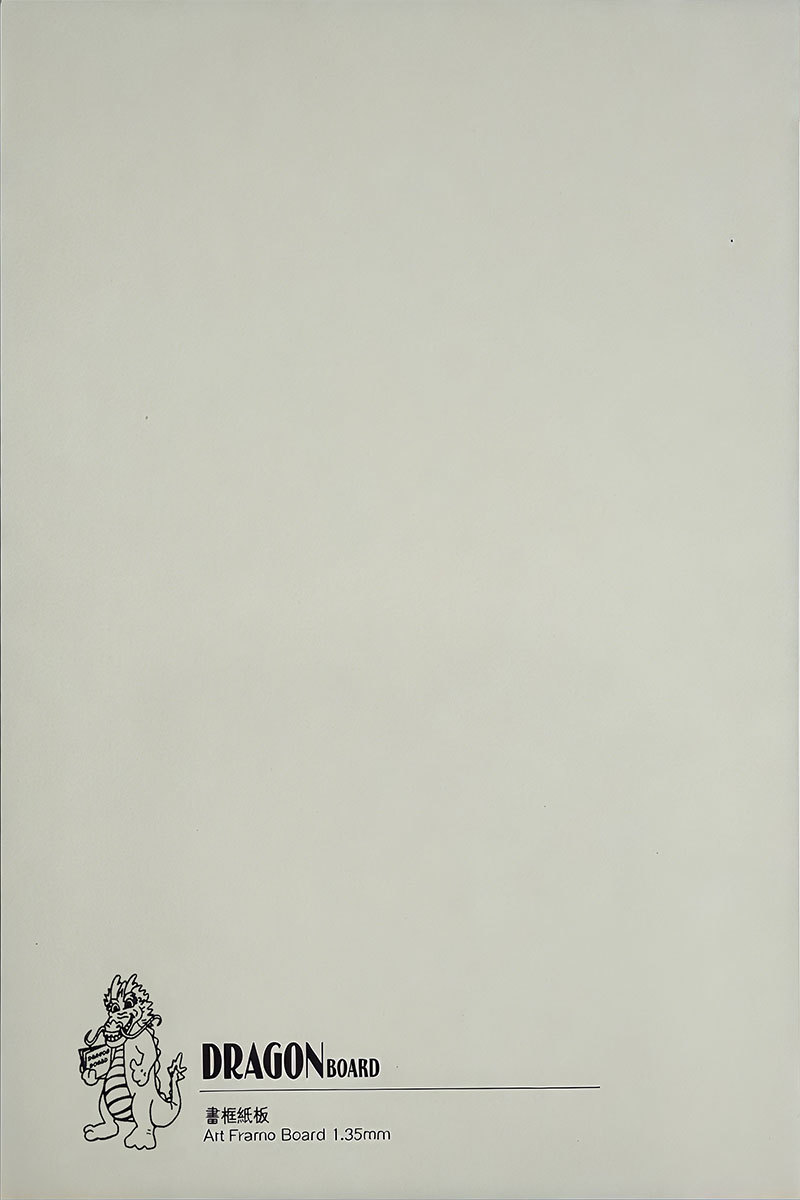

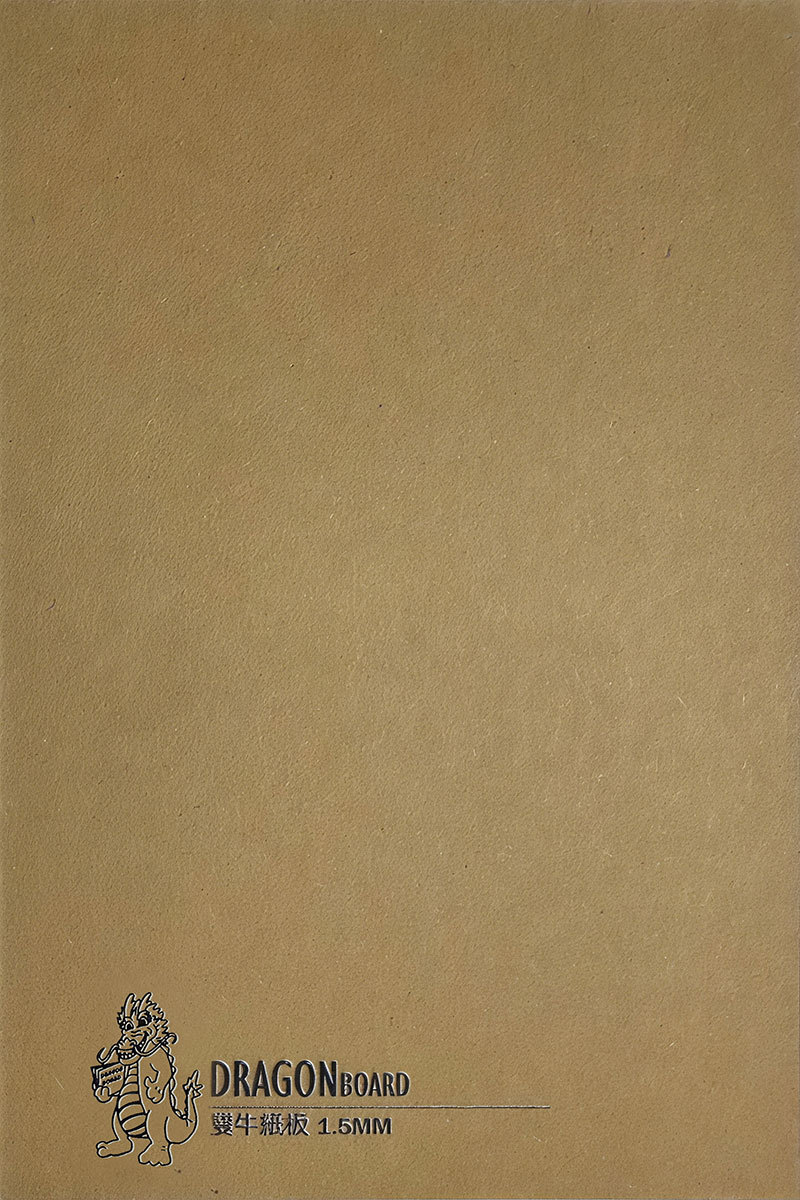

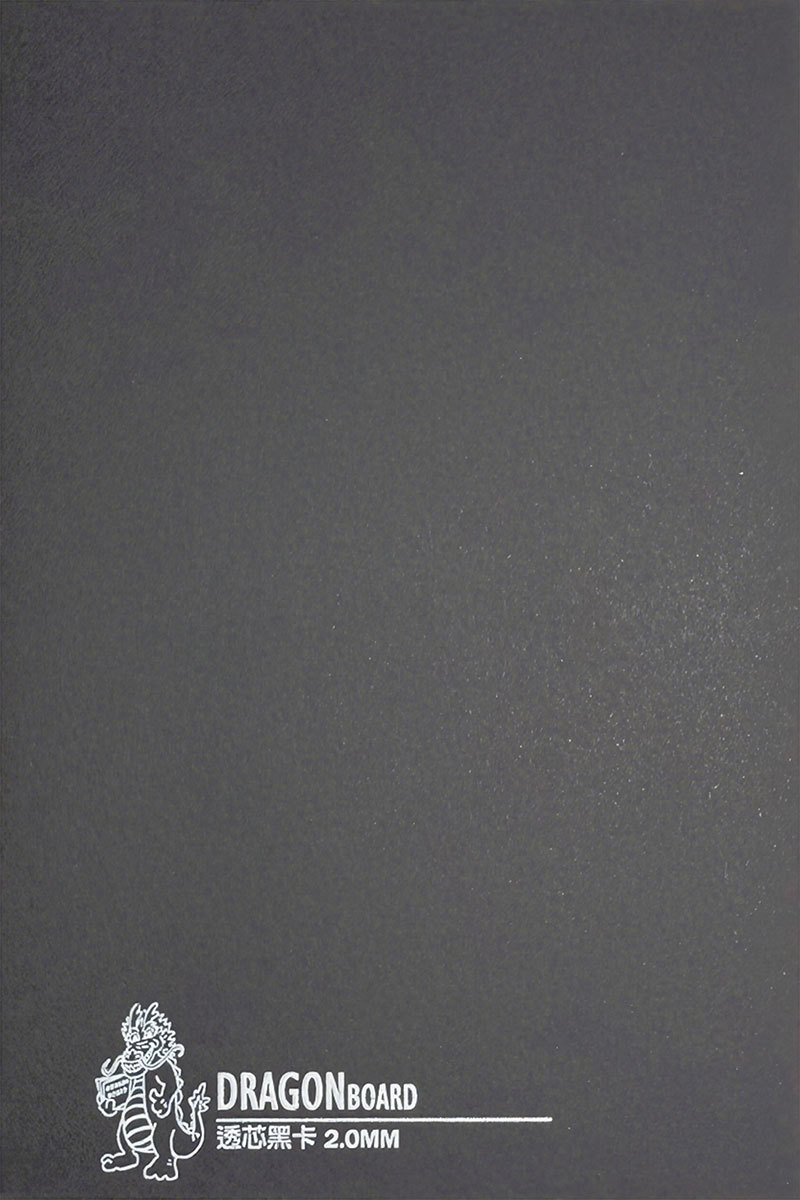

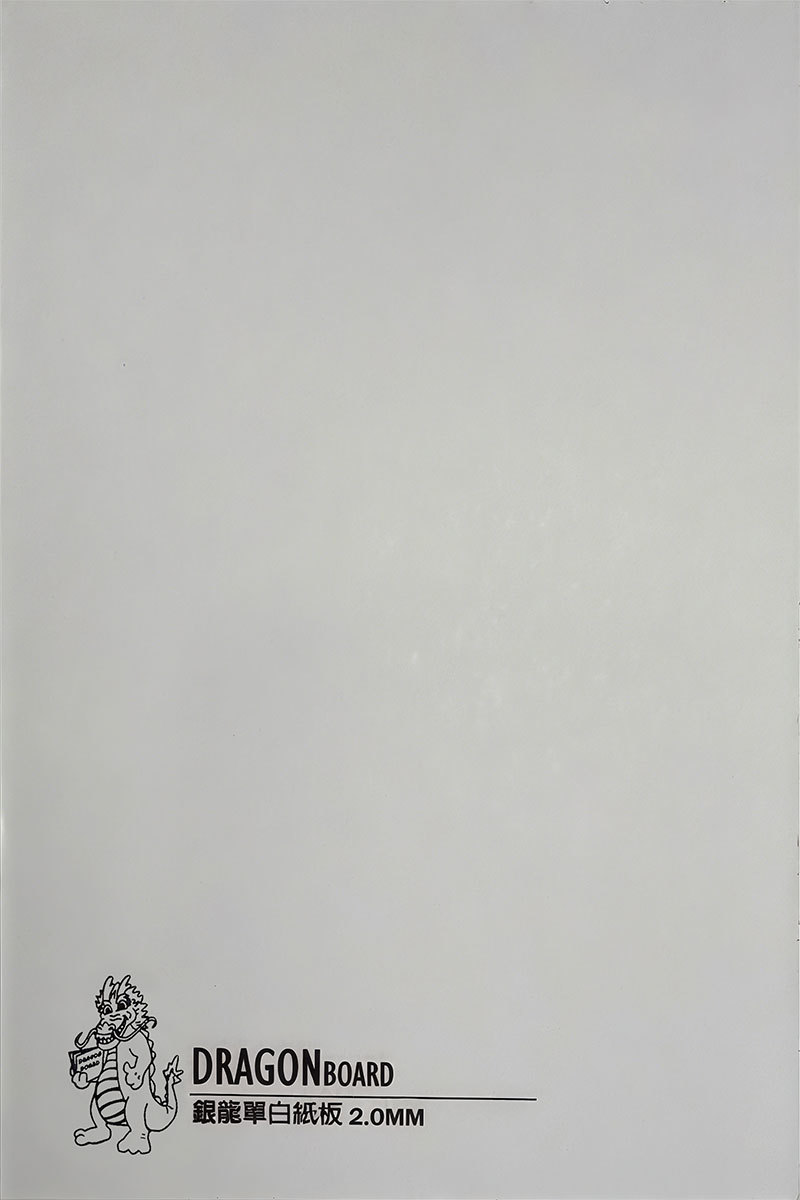

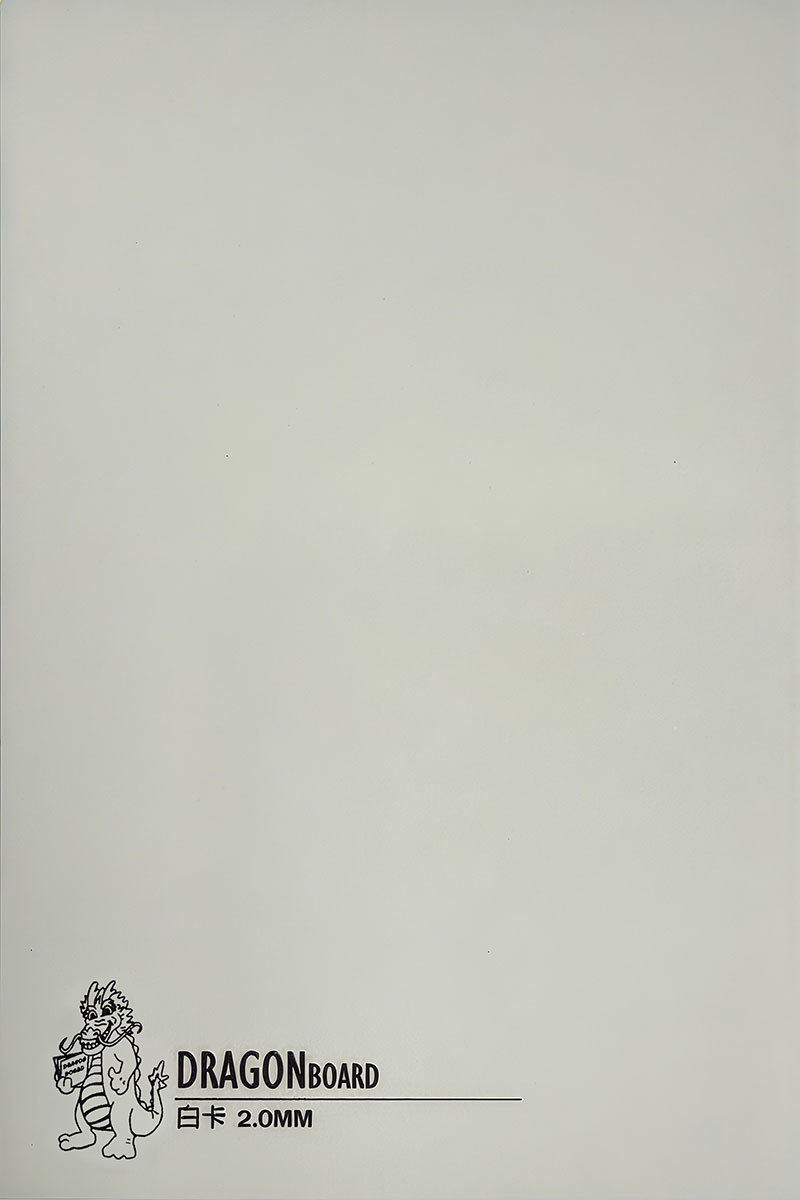

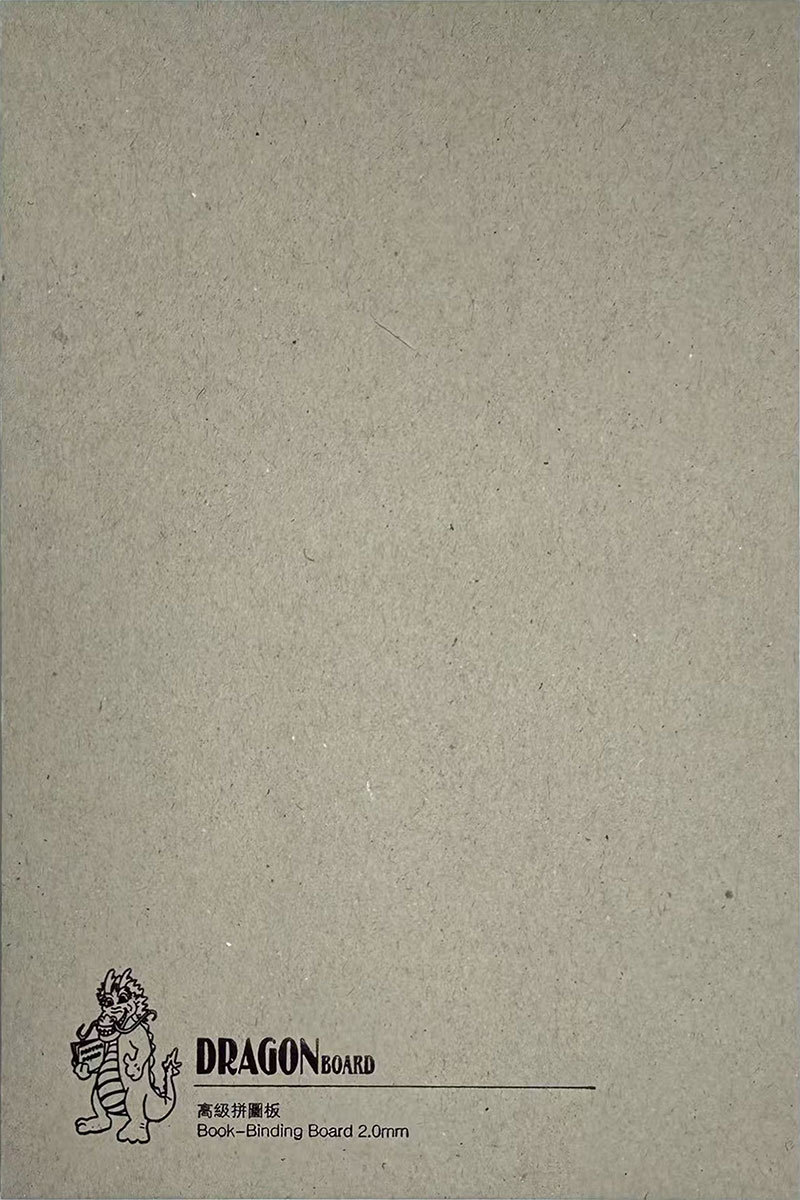

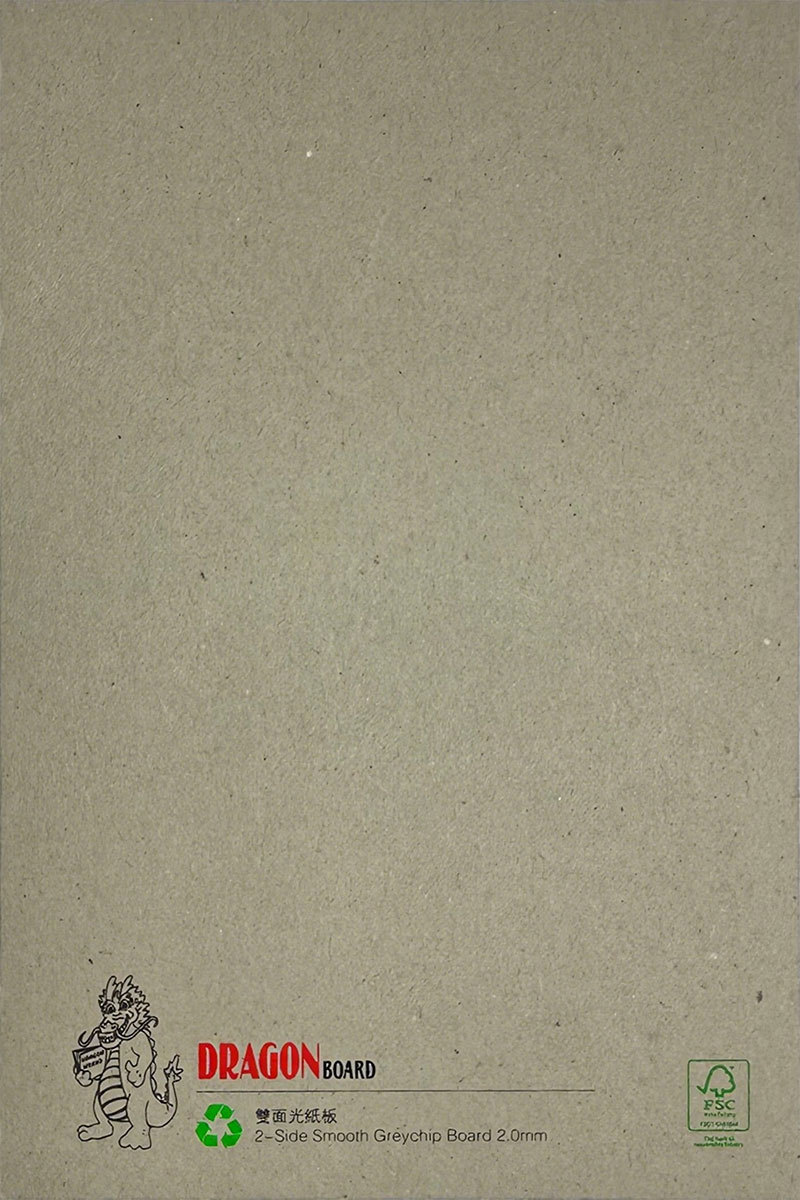

IN CHA Group specializes in the production of DRAGON Board—high-quality grey cardboard designed specifically for hardcover books, puzzle boards, puzzle-colored cardboard, packaging gift boxes, picture frame boards, kraft boards, solid black core boards, white-core chipboards, single-white chipboards, as well as moisture-resistant, waterproof, antistatic, and anti-counterfeit cardboard products. These materials are now widely used across industries such as printing & packaging, stationery, automotive, 3C electronics, premium cigarette packaging, cosmetics, and food products.

Founded in

Company Area

Partners

Product Center

IN CHA Group specializes in producing DRAGON Board, a high-quality grey cardboard specifically designed for hardcover books.

01

Production equipment

02

Management System

03

Quality Certification

04

After-sales Quality

Scope of Business

Selling globally—Europe, North America, Southeast Asia, and Asia

Light Industry & Papermaking: Paper Prices Slightly Drop, While Raw Material Imports Decline

2023-06-27

Learn more +